When it comes to home improvements and renovations, we often look internationally to find inspiration. Many homes and businesses in Canada that are designed by modern-day architects and interior designers, most often than not, have a unique edge to them. This region is well-known for its original architecture and modern-day once-off unique pieces, see here. The majority of the things that are done are bespoke and according to either their ideas or the ideas of the owners, depending on if they’ve been given carte blanche. Which is what most celebrities and famous people go for nowadays.

If you are one of these proud homeowners, the advice any good designer can give you to get an edge in your home, is to get customized lighting and brilliance that has been tailor-designed to an aesthetically sound appeal. One that no other home has.

For this to happen not only do you need to decide on the aspects around it, but you will also need to choose the right designers and companies that do bespoke lighting designs such as https://karicelighting.com: custom lighting in Canada, and this is something that is few and far between other retail or home stores and services.

The process that these companies go through to get you that perfect model, is an intricate one and this article will discuss this and give you some ideas of what you can choose.

The Process Of Customized Lighting

There are those designers that get their inspiration from “their dreams”, and then there are those that sit down will well-calculated paper and ink and go through each step until the final and perfect outcome, that they can see in their mind’s eye placed in its form in the right place inside the house. We look at this latter type.

Typically with any type of design work, there are 5 steps involved.

Step 1. Concept

Step 2. Engineering and Designing

Step 3. Production

Step 4. Certification

Step 5. Installation

Step 1. Concept

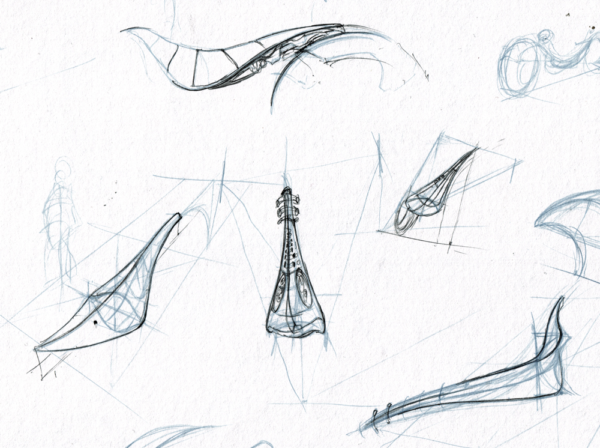

This is the first step that turns an idea into a sketch or a mock-up. When developing a design concept the idea revolves around how to solve a design situation that is in front of you. This is an important part of the process of customizing the lighting. Having spoken to a few of these custom lighting companies, the common theme is that their clients go to them with some sort of sketch or idea in their mind which they then turn into a concept.

Often it is the things that have never been done before, that are the most sought after. Having put their expertise down to paper, they then develop a fully functional concept of the mockup.

Step 2. Engineering and Designing

Karice lighting, for instance, is not only lovely looking pieces, but they are also a result of engineering. Designing a piece of the light source is one thing, but making sure it is fully functioning is another. Plus it needs to be cost-effective for both the client and the company creating it. In this step, extensive planning and testing are the two main components here.

Step 3. Production

In this step, three fundamental things take to process, namely, the production, which involves fabrication, hand finishing, and machining where needed, find out the difference between each one here. During this production phase, one needs to get their creative caps on. This is the journey it takes to become something unique.

Some of the pieces require a hand finishing, while others suffice with the use of a machine. Generally speaking, the wilder the idea the more hand finishing will be needed for those impossible nooks and crannies.

Step 4. Certification

With the majority of the electrical manufacturing sectors in Canada, there needs to be a thorough quality check done. In lighting manufacturing, it’s the same. The lighting certification in question, for each unit, will come from the private testing body of the CSA or Canadian Standards Association, and the UL or Underwriters Laboratories Quality Checks.

This is the authorized body that administers the UL certificate, which is a design certificate that will establish that the item is of proper use and safe functionality. It needs to abide by strict guidelines.

Step 5. Installation

This final step involves the installation of the said item either at the client’s premises or in the showroom for the client to see so they can do it themselves at home. Seldom does the client want the same company to install the lights for them and as such, it is shipped to their premises.

Knowing the end-user of the light and the space in which it will go is fundamental to all the processes because it needs to fit the environment in which it will go and look like a part of the surrounding, or stand out completely if the client wishes.